Energy chain bend radius calculator

Do I need a bend radius calculator? Calculating the bend radius for a cable management system can be a daunting task, but ensuring you choose correctly to maximise the service life of your cables is paramount.

We get asked a lot, “Do you have a bend radius calculator?” or “How do you measure the bend radius?” So, let’s look at answering those questions for you.

One of the most crucial factors in specifying the right energy chain system or cable carrier, as it is sometimes referred to, is ensuring you select the correct bend radius for the cables being carried. It is important to note that the bend radius of the energy chain should be larger than the minimum bend radius of the cables and media that make up the filling. There are exceptions to that rule, such as applications with space restrictions, but it must be recognised that this will reduce the service life of the services significantly.

A bend radius calculator step by step:

- All energy chain systems have multiple bending radii to choose from and every manufacturer should suggest a minimum bend radius. The bending radius chosen for the energy chain will depend on the largest diameter for either the cable or hose. But why do manufacturers suggest this? By selecting a larger bend radius than required, this will extend the lifespan of the cables and hoses.

- Never exceed the manufacturer’s suggested minimum bend radius. Just don’t!

- As mentioned previously, the larger the bend radius, the less stress is put on the cables and hoses, which will ensure longer service life.

- Consider temperatures. The minimum bending radius is partly based on a temperature range for flexing; therefore, consideration is required with special environments and applications where temperatures exceed the recommendation for the cable. The same applies to extremely low temperatures. For these low-temperature applications, the cables tend to stiffen and become brittle when exposed to the cold, leading to mechanical failures.

- Ensure the energy chain system is being fitted with the correct matching dynamic cables for your application.

- If the application has a space restriction, the bend radius of the energy chain system may need to be smaller than that of the recommended minimum bend radius. Again, referring to previous statements, this is far from ideal but occasionally it cannot be avoided. In these special circumstances, we would recommend using cables specially designed for low-bend radius installations or consult your cable carrier manufacturer for the best solution.

- Remember this is a dynamic bend radius; many cable and hose makers quote what is actually a static radius. As soon as the service is being moved dynamically, fatigue can set in and therefore the dynamic radius is typically larger (igus® cables are quoted as dynamic radius for millions of cycles).

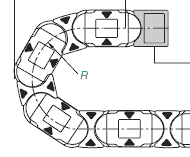

Do you know how to measure or define an energy chain's bend radius?

The bend radius is defined by a point in the space at the centre and is measured to the centreline of the e-chain® (see diagram). The reason the centreline is used is that this is where the cables and hoses sit and therefore can be matched to the recommended minimums suggested by the cable manufacturer.

In most cases the minimum bend radius is expressed as a factor times the outer diameter of the service (e.g. for chainflex cables this can be from 12.5xd to as low as 4xd for our special cables).

Still not sure on the bend radius calculator? Speak to your local engineer or contact an igus® contact in the office and they will help you.

Comments

Post a Comment