Obsolete

parts, isn’t it incredibly frustrating when a component in your machine or

application breaks and you find out the OEM has discontinued it? This can be

costly if it means that individual component is no longer available potentially

rendering the machine useless.

But what do

the terms “obsolete and obsolescence” truly mean?

Obsolete or obsolescence

“Obsolescence is the state of being which occurs when an object,

service or practice is no longer maintained, required or degraded, even though

it may still be in good working order”.

“Obsolete also refers to something that is already disused or

discarded or antiquated. Typically, obsolescence is preceded by a gradual

decline in popularity”. – Both quotes were taken from Wikipedia but

give a clear insight as to the definitions and differences of the two terms.

There are

disadvantages and advantages of obsolete parts. Disadvantage, as mentioned

earlier, can mean expense if you are unable to locate a replacement.

However, an advantage, you have the potential and freedom to design an

improved part!

Luckily,

technology has advanced to the point that obsolete parts should be a thing of

the past.

igus®

has many methods of helping solve this issue: from 3D printing parts to machining from

stock materials.

I have

identified 3 ways to help solve the obsolete part issue….

- 3D print

- Machine from stock materials

- Complete redesign of part

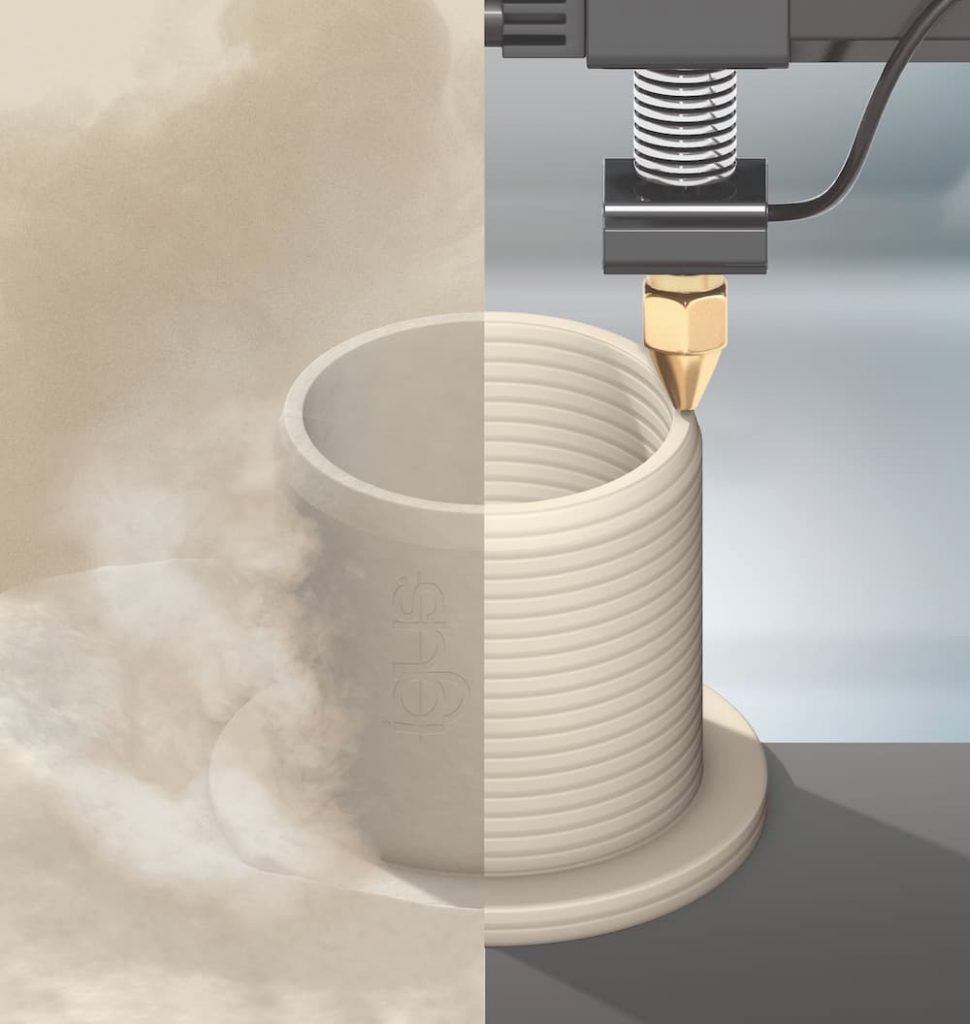

3D print

3D printing is

ideal for obsolete parts. It is cost-effective with no set up costs, it allows

flexibility if you want to adjust the component design and it is quick to

produce.

With igus® 3D printing options

using either FDM filament or SLS (selective laser sintering), you have the

additional benefit of using an igus® material that

is not only hard wearing but has the high performance tribological properties

that all igus® materials

have. With the 3D drawing system, you can drop a CAD file into the

configurator, select the best material based on the parameters shown and order

it. It really is that simple.

Machine from stock materials

We can assist

with this option too. We can help you take a physical part, model it and quote

it. With a large variety of igus® materials to choose from, it allows

flexibility with design whilst still offering technical material properties.

With no minimum order quantity, this method of manufacturing obsolete parts is

perfect if you need something specially designing. We have capabilities of

machining using CNC milling, turning, routing and even laser cutting, whichever

method is the best and most cost-effective.

An example of this process:

Not long ago

we had a new customer who required a problem solving. He had a milling machine

that had obsolete steel bearings that could no longer be sourced due to the age

of the machine. The customer had the measurements and the worn piece.

After some lengthy discussions we settled on producing the parts in iglidur®

J material. We had a very similar application that we had worked on a few years

ago so we had an idea of what to do. Luckily having engineers all over the world allows us to share our expertise along the way!

The

discussion had been coupled with the igus® online expert systems to

provide wear data on the parts to give a predictable lifetime. If the

application information is available for the loads, speeds, shaft material,

shaft size and housing materials along with the dimensions then the online

calculators on our website are a great aid to planning your parts.

The part was

then drawn in the iglidur® J material and samples sent for in

application testing.

Testing went

well, and the problem was solved using igus® technical polymers. We

have materials to cover all industries, and we will aim to provide the best

material for your application based on data we hold in our system and from our

tests results.

Complete redesign of part

Sometimes the

part that has become obsolete is so worn that it is beyond recognition! This

can make recreating and manufacturing the part tricky but with the expertise of

the igus® engineers in all that is plastic, we are able to guide you

through recreating the part. Not only that, we offer samples for testing and

can tweak the design along the way.

We are

currently working on a new system for the website that will allow customers to

add their part and not only get the best material selected for the application,

but also the price and lead time!

This will be

a great tool for customers to use alongside any assistance that is required by

the igus® experts, so watch this space!

Obsolete

parts are annoying but no longer mean the end of a machine’s life, so talk

to us, we can help.

Comments

Post a Comment