Sustainable cars? The entire world is focusing heavily on sustainability and becoming CO2-neutral. This is vital for the world to start to repair the damage being done every day. So, it is our responsibly to start fixing what is broken.

This is easier said than done. How do companies become sustainable? And can industries that rely on products which are labour intensive to produce help with this uphill battle? Industries, such as automotive. And in an industry renowned for dirt, grease, fumes and expense, the question is, is there such a thing as a sustainable car?

Within the automotive industry, there is an added pressure of the recent introduction of stricter emission regulations. This development is being driven by society’s growing awareness of the environment and sustainability. It is also being pulled heavily from consumers’ increasing interest in sustainable cars.

What constitutes a sustainable car

A sustainable car needs to be produced in an eco-friendly way, impact the environment less and ideally use different methods of power over diesel and fuel. To meet the increasing demands, the industry must develop sustainable solutions and focus on both the product and the value.

How do we meet these demands?

At igus® we have set ourselves the goal of achieving CO2 neutral production by 2025. As a “plastics” company this is seen as a huge goal, even more so than other companies. This is purely based on the negative connotations of being a “plastics” company. However, our igus® polymers are different and help make a significant contribution to the increasing challenges faced.

But how can a polymer plain bearing help make products more sustainable? And how can it help make sustainable cars?

Background information

The production of the plastic granules requires about 50% less energy than the production of metal. The energy requirement for injection-moulded plastic plain bearings is also about half that of metal bearing alternatives. This is mainly due to the lower processing temperature and lower weight.

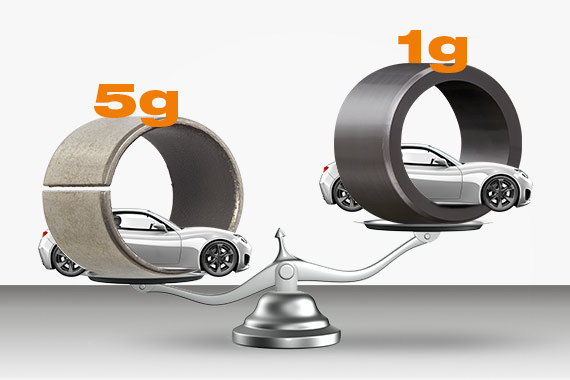

In vehicle design, the construction being lightweight is paramount. So, with polymer plain bearings being up to 7x lighter than metal versions, these are being designed in from the initial design stage. This is characterised by electro-mobility. Lighter weight means lower consumption, and a therefore longer range. The lightweight construction also significantly reduces consumption and emissions in combustion engines.

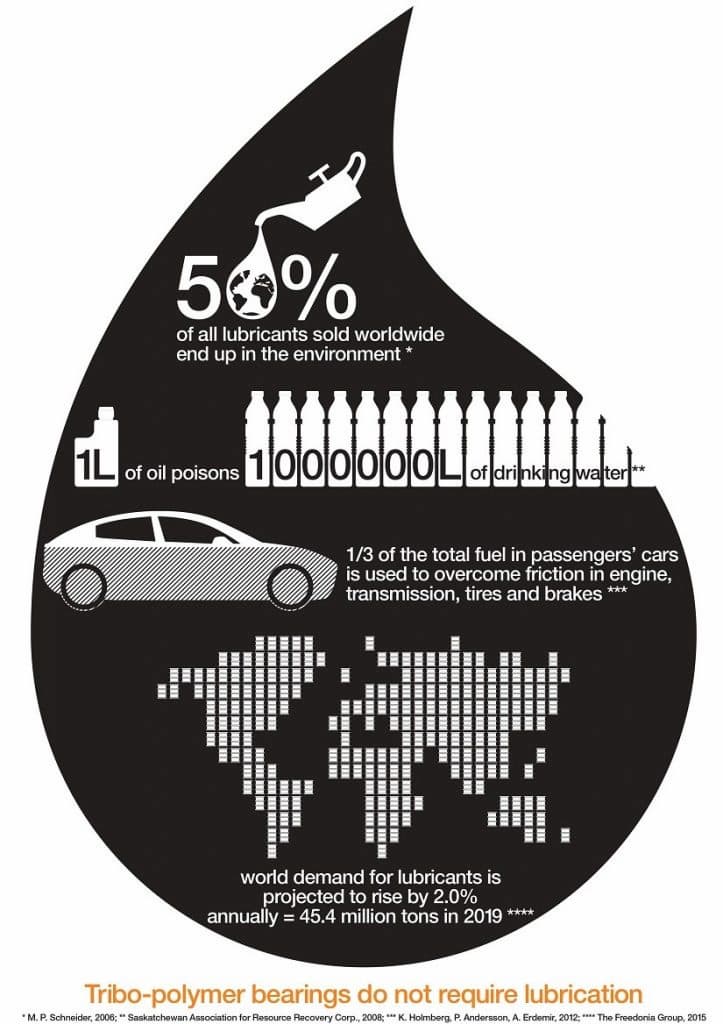

Another advantage of iglidur® polymer plain bearings in terms of sustainability is the elimination of lubricants. Bearings made of iglidur® materials contain integrated solid lubricants and do not require additional lubrication. The impact of lubricants on the environment is frankly shocking:

- Up to 50% of all lubricants sold worldwide end up in the environment.

- 1L of oil poisons 1 million litres of drinking water.

- 1/3 of the total fuel in cars is used to overcome friction in engine transmission, tyres and brakes.

Other sustainable advantages

In addition to the above sustainable advantages that iglidur® plain bearings can bring, there are other requirements that play an important role in sustainable automotive design.

Sustainability can be achieved with cost reductions

The automotive industry faces greater price pressure than any other industry, forcing suppliers and designers to continuously reduce costs where possible.

iglidur® plain bearings are a favourable alternative to expensive metallic options, such as composite metal bearings and rolling bearings and offers cost savings of up to 40%. In addition to lower production costs, intelligent injection moulding designs and lack of lubricants reduce costs by eliminating assembly steps. This not only reduces costs, but it reduces downtime, weight and with a lack of lubrication, has a positive impact on the environment.

igus® can help with offering design freedom

Manufactured in the plastic injection moulding process, individual designs can be generated almost without restriction in the in-toolmaking department. In various applications, iglidur® plain bearings are perfectly adapted to the geometries of obscure housing shapes. Time-consuming assembly steps or subsequent forming processes are eliminated or reduced, again leading to a more cost-effective and sustainable way of designing and building vehicles.

If you need any help with specifying parts on vehicles, please speak to Aw Kai Hua our Automotive expert today!

Comments

Post a Comment