Which drylin® liner material is ideal

for my application?We know it can get confusing and overwhelming when trying to choose the right

liner material for your drylin®

W or

R system since there are so many options available. That’s why we wanted to provide you with this at-a-glance overview to make the process a little easier. FYI: Another useful tool is our

online configurator where you can mock up your application and compare the lifetimes of the different materials.

All

our

liners

can

be

purchased

separately,

or

they

can

be

integrated

into

our

adaptors

as

well

as

our

standard

and

flanged

pillow

blocks,

making

them

dimensionally

interchangeable

with

linear

ball

bearing

guides.

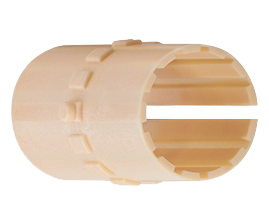

Our liners are specially designed with fluted ID’s (inner diameters), which help mitigate thermal expansion and dial in a more precise fit than a typical press-fit plain bearing. These flutes on the ID also act as “dirt channels” in applications contaminated with debris.

Now, let’s get into the overview of our liner materials so you can start designing

your appli- cation sooner than later.

iglide® J:

The original yellow “all-arounder”

iglide® J is our original liner material and works well on every shaft material that we offer.

The iglide® J liners are also available

in a low-clearance version, which cuts the ID tolerance

of the bearing

in half. They are available

in

both metric and imperial

dimensions.

Standard Clearance Low Clearance

Standard Clearance Low Clearance

iglide® J200:

Aluminum

shaft/rail specialist

iglide® J200 is a material that has been optimized to work specifically with drylin® aluminum shafts and guide rails. It exhibits a lower coefficient of friction than iglide® J and offer a longer service life. These liners are available in metric and imperial dimensions

Technical Properties:

• Ideal for hard-anodized aluminum shafts – best coefficient of friction, longest service life

• Application temperature: -58°F to 194°F

• Max. static surface pressure: 23 MPa

• Moisture absorption: 0.7 % weight

iglide® E7:

Aluminum shaft/rail specialist

iglide® E7 has been tribologically optimized for long service life on steel and stainless-steel shafting. This material has the longest lifetime of any material we have tested – competitive or otherwise – on the market. iglide® E7 liners are available in both inch and metric sizes.

Technical Properties:

• Ideal for steel and stainless-steel shafts – best coefficient of friction, longest service life

• Application temperature: -58°F to 158°F

• Max. static surface pressure: 18 MPa

• Moisture absorption: 0.1 % weight

iglide® X:

High temperature and

chemical problem solver

iglide® X, also known as T500 in North America, has long been the go-to material for high temperature linear applications as well as applications requiring extreme chemical resistance. It is not recommended for use

on aluminum shafting but works well on stainless and hard-chromed materials. iglide® X liners are available in imperial and metric dimensions.

Technical Properties:

• Ideal for hardened stainless-steel shafts/guides – longest service life

• Application temperature: -148°F to 482°F

• Best coefficient of friction with hard-chromed stainless steel

• Max. static surface pressure: 150 MPa

• Moisture absorption: 0.5 % weight

iglide® A160:

Blue-sky thinking

FDA/EU-compliant

iglide® A160 is one of our latest material innovations. It features FDA compliance for food and pharma packaging and processing machines. The material has extremely low moisture absorption and would work well in any underwater or high humidity applications. The best shaft material to pair with it is hardened 400-series stainless steel. iglide® A160 liners are available in metric dimensions

Technical Properties:

• Ideal for hardened stainless-steel shafts – best coefficient of friction, longest service life

• Application temperature: -58°F to 194°F

• Max. static surface pressure: 15 MPa

• Moisture absorption: 0.1 % weight

iglide® A180:

FDA-compliant

Another liner in our FDA compliant product offering is our iglide® A180 material. A180 can withstand higher loads than the A160 material and works well on all shafting materials. These liners are available in metric dimensions.

Technical Properties:

• Ideal for hard-anodized aluminum shafts

• Best coefficient of friction, longest service life with stainless steel shaft

• Application temperature: -58°F to 194°F

• Max. static surface pressure: 23 MPa

• Moisture absorption: 0.2 % weight

Comments

Post a Comment