What is the “virtuous circle”?

According to Merriam-Webster, the definition of “virtuous circle” is: “a chain of events in which one desirable occurrence leads to another which further promotes the first occurrence and so on resulting in a continuous process of improvement”. This is apparent in everyday life. Every day there are events which can be considered part of a virtuous circle, generosity brings out more generosity, innovation generates income which allows companies to invest in further innovation. It is more common in everyday life than we realise.

How are igus® products part of the virtuous circle?

Even the basis of igus® products fits into the “virtuous circle” idea. Our products are not part of the “throw away” society and are plastics for longer life. The principle behind this is that despite being manufactured in plastic, they are better for the environment than their metal counterparts.

Cradle-chain E2

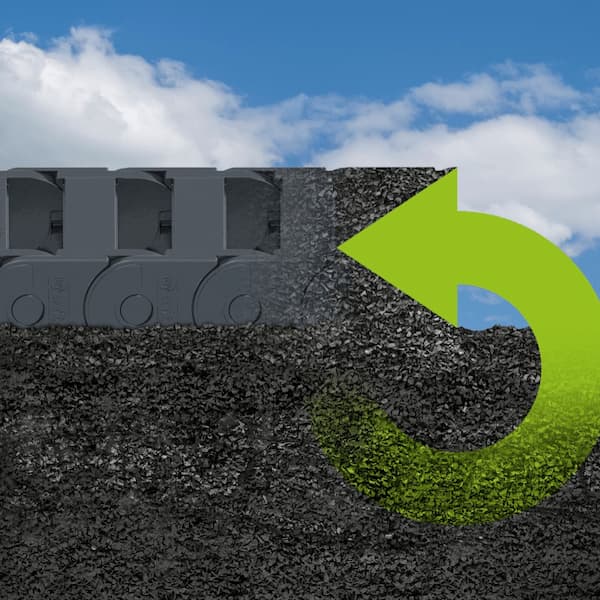

One of the most innovative energy chain products to be released this year was the cradle-chain. This is the first energy chain to be released worldwide made from 100% recycled material. The term “cradle” comes from the “cradle-to-cradle” concept. This refers to processes which are “sustainable and considerate of life and future generations—from the birth, or “cradle”, of one generation to the next generation”. This sums up the cradle-chain process perfectly.

The idea for this new method of manufacturing these chains came from the chainge programme that we run, where we recycle old energy chains into other products. Based on this idea, the new E2,1, C.G e-chain® was designed, developed and released. As with all igus® products, this new fully recycled chain has been put through its paces in our in-house test lab and has been vigorously tested.

The new fully recycled energy chain

Taking the old energy chains as part of the chainge programme made us realise that we could regranulate, clean and sort them to give good enough material to produce new chains. The chains themselves offer almost the same technical specifications of the standard energy chains of the same size, with only a very minor reduction in load capacity, temperature range etc.

This innovative method of manufacturing energy chains offers a 28% CO2 saving and is classed as a sustainable raw material. This therefore falls under the term “virtuous circle”.

There are currently 5 available series of this chain available, but I have no doubt that more will follow in their footsteps.

As part of the igus® promise, this range of chains is tested thoroughly under typical real-life application scenarios, allowing us once again to be able to provide accurate data on aspects like tensile strength and breaking moments, the same technical data available for the standard range of igus® energy chains.

A big step in the fight against plastic waste

Becoming part of the “virtuous circle” has allowed us as a company to have a further positive impact on the environment. If we can create more recycled products from products at the end of their life cycle, then as a company we become even more sustainable.

We have also created a range of “Eco” bearings which are plain bearings that have been manufactured using regranulated iglidur® material. The bearing material range covers high temperatures, high media-resistance, versatility, robustness and cost-effectiveness. This bearing range ensures that the same beneficial iglidur® properties are present in the bearing while contributing towards a more sustainable future.

Comments

Post a Comment