What are the advantages of optimising a moving application?

Due to installation space, encoder and motor cables are usually laid parallel to each other. They are from the same control cabinet, go through the same cable conduit, move together through the same energy chain and are finally fastened to the connections of the motor that lie side by side. The mutual influence on signals when network, encoder or servo signals run side by side is often difficult to estimate.

The initial impulse of the motor (starting current) as well as the length of the connecting cables or possible surrounding conditions (e.g. a shaft furnace in close proximity, a welding cell, a frequency converter or other sources of disturbance) have a significant influence.

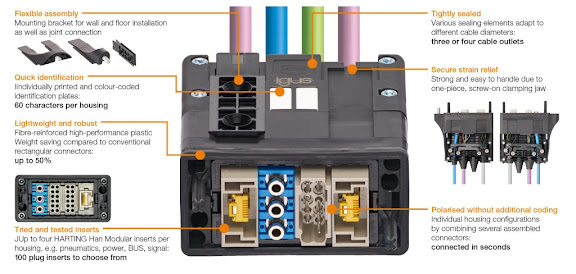

Furthermore, every interface increases the risk of the plant being affected by external sources of disturbance. Often, Intermediate connections are inevitably screwed onto sheet metal via connector housing and sleeve housing. Especially when a machine is modified or converted during construction process, the cable must be lengthened, many operators will change to new cables instead of using extension cables with male and female contacts. The intermediate connectors have an advantage for handling individual assemblies. However, they are detrimental to the machine when they are badly processed. With connector plates included in the plant, the entire machine can be divided to easily manageable assemblies. These assemblies make your system modular. Components can be replaced with only a few steps.

Advantages of optimising a moving application

Do the advantages of the modularity in assemblies outweigh the risks of electronic magnetic interferences?

In the meantime, there are different solutions for assuring an assembly to be managed in a modular way or is reliable in use. In this article, we would like to present a solution for optimising a moving application with a clear coding of elements to ensure connection security e.g., (for untrained staff, small installation space or adverse lighting conditions.)

Reduce standstill times, simplify handling, optimise process

Explained by using the example of an automatic production line:

All connecting cables and further movable parts, such as the energy chain, can be optimised with modular plug-in connectors that are individually adjusted to the application. This enables a defined and easy-to-handle interface that facilitates the exchange of an assembly.

Reduce overtime

E.g., of individual manufacturers or special machine builders:

Normally, the control cabinet is placed at a certain distance from the field in which the motors, encoders, sensors, light barriers, safety contacts and emergency off-switches are kept.

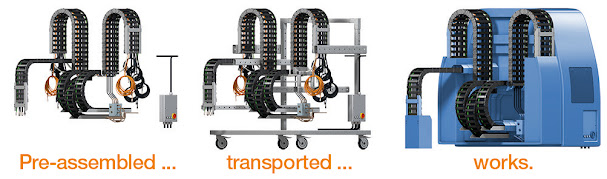

Before commissioning (IBN) at the end customer’s site, every plant is set up, parameterised and tested at the manufacturer. All components are connected according to the specification. After the successful final control, the plant is disassembled into a few basic modules and packed for transport. The transport route or the packaging options are crucial here, the finally tested plant is disassembled correspondingly. At the production site of the end customer, the individual parts are delivered to their destination and connected again. The IBN technicians often spend several days on setting up and connecting the plant again according to the documentation. At this time errors can occur and needs to be amended.

Simple maintenance, safe operation

E.g., for machine tools:

Highly cyclical and fast applications that are typically required in machine tool can benefit from a modular assembly. Electric cables and hydraulic hoses are used in a multi-axis system, which is installed in the corresponding machine as an assembly. At this point, materials and components must match with each other to ensure a smooth production and long service life.

The examples shown above illustrate the possibilities of optimising your processes. In case you are interested and would like a personal consultation, the igus® project managers are happy to help you. We will advise you individually concerning modular plug-in connectors (Module Connect) or interface-optimised energy supply systems (readychain® Standard or Standard +).

We are happy to inform you of our ready-to-install energy chains on transport racks (readychain® Premium on readychain® rack), which can be installed directly at defined mounting points in your machine.

Would you like to obtain some information first? – Here you can go to our readychain® site.

Or visit our Module Connect site.

Comments

Post a Comment